Powders and Particles

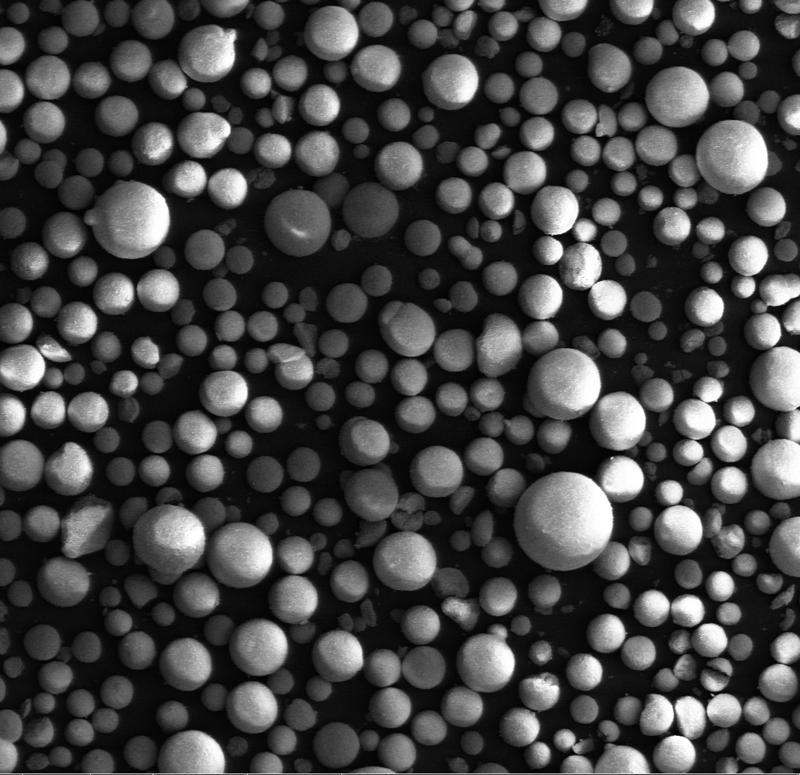

Powder-to-powder interactions are essential to understand for a wide range of industrial processes such as pharmaceutics, ceramic powders, paints and coatings of metal components, catalysts, batteries, and additive manufacturing.

Powders and Particles research solution by LiteScope is a groundbreaking platform that facilitates real-time measurements of the morphological characteristics of individual particles and offers advanced surface roughness analysis capabilities.

Determination of surface roughness of Powders and Particles

- Key characteristics influencing the production process and functionalities.

- Enabling optimized production of P&P with specific properties.

Testimonials

LiteScope pioneers direct analysis of ceramic powder roughness, revealing correlations with macroscopic properties.

Highlights of AFM-in-SEM Powders and Particles solution capability

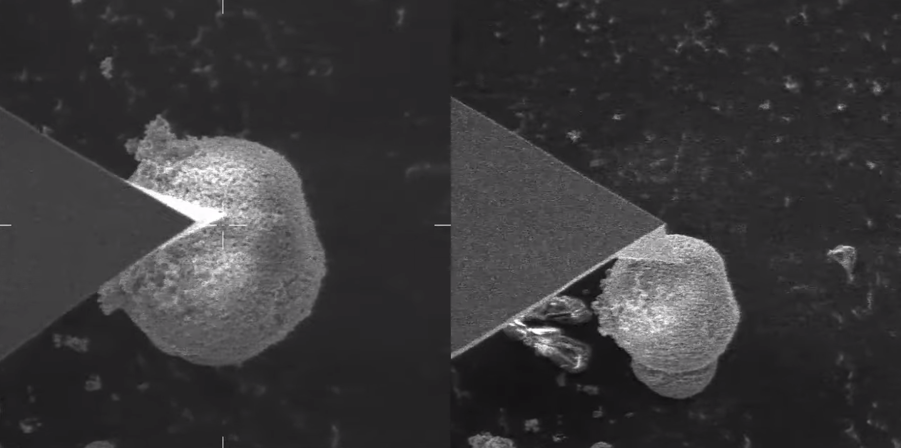

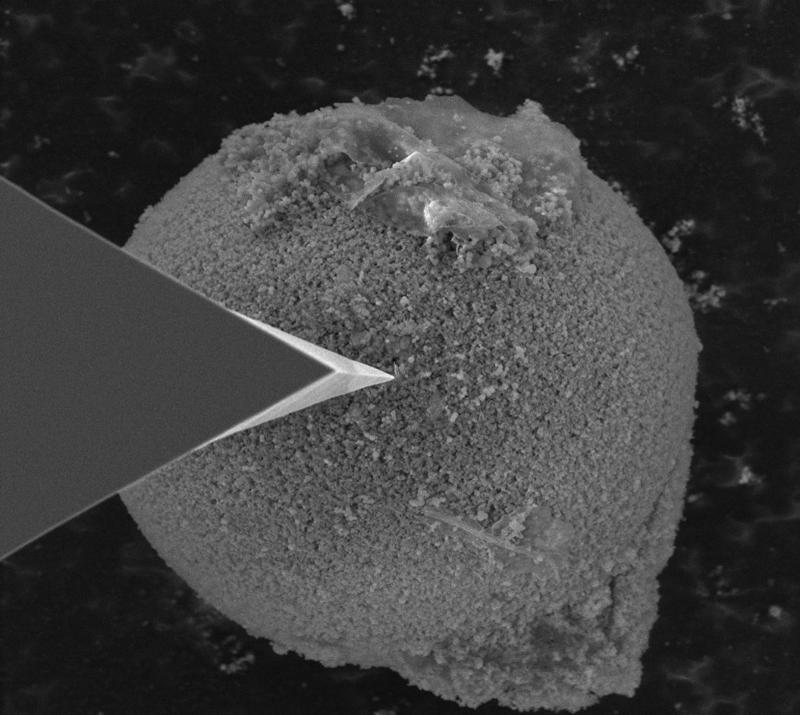

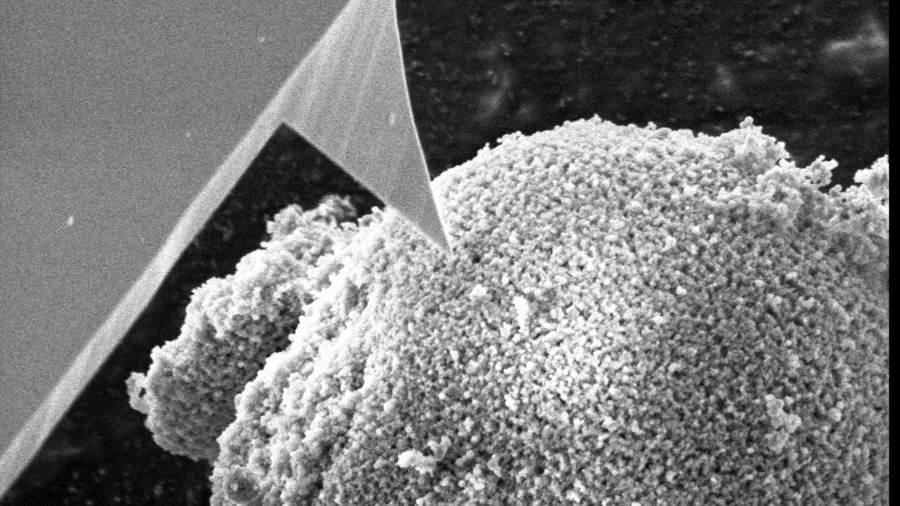

- Direct measurements of topography and surface roughness of individual particles or powder with sub-nanometer precision.

- Analysis of surface texture and decorations on the particles or powders created by additional functionalized materials.

- Precise localization of specific particles by SEM and use of additional SEM.

- To determine particle composition (EDX) or SEM contrasts (SE, BSE).

Key benefits

Optimize your processes and experience a workflow that makes your tasks smoother and more time efficient.

Access a dedicated toolbox for particle surface roughness analysis, featuring specialized tools for accurate surface roughness measurements, including background corrections to simplify complex calculations.

Fast and effortlessly export data for further processing and reporting, making it simple to share your findings and collaborate effectively.

Key application areas

Powder-to-powder interactions are essential to understand for a wide range of industrial processes such as:

- pharmaceutics

- ceramic powders

- paints

- coatings of metal components

- catalysts

- batteries

- additive manufacturing

Webinar

Watch our webinar to delve deeper into the key benefits of employing AFM-in-SEM for the characterization of powders, particles, and 2D materials.

- How to effectively measure and determine the surface roughness of powders and particles.

- About the importance of multimodal study of low-dimensional materials for understanding the advanced properties of new functional 2D materials.

- Practical examples from the pharmaceutical and ceramic industries.