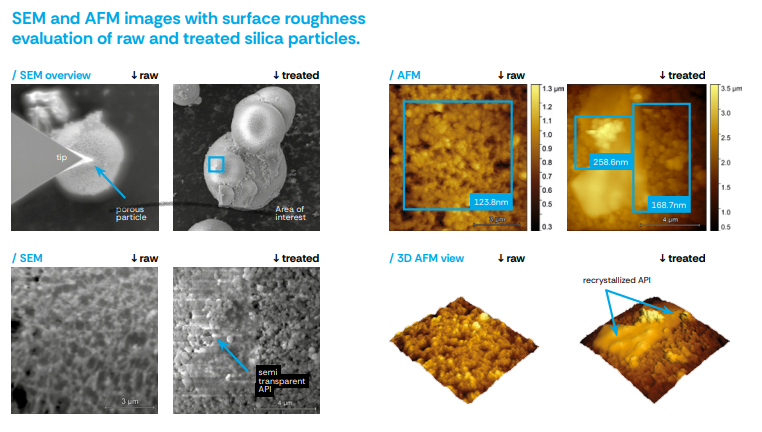

Key benefits in the characterization of Powders, Particles, and 2D materials by AFM-in-SEM

Webinars

|

28. 02. 2024

Material Science

Related articles

Scientific articles

|

17. 12. 2024

|

by ACS Applied Electronic Materials

Impact of Electron Irradiation on WS2 Nanotube Devices

Material Science

Technology

Scientific articles

|

18. 11. 2024

|

by Materials

Enhancing Thermoplastic Starch with Maltodextrin: Key Properties and Performance Insights

Material Science

Technology

Scientific articles

|

12. 08. 2024

|

by Scientific Reports

3D Surface Roughness Measurement of Core–Shell Microparticles

Product

Technology

Scientific articles

|

25. 06. 2024

|

by Production Engineering

ZrN coating as a source for the synthesis of a new hybrid ceramic layer

Product

Technology

Webinars

|

12. 03. 2024

Unlocking the Secrets of Battery Materials: A Dive into AFM-in-SEM Characterization Webinar

Material Science