LiteScope 2.5 released

AFM-in-SEM is setting a new standard in the In-Situ Correlative Microscopy

We are thrilled to announce the release of our new product LiteScope 2.5. This launch of LiteScope marks a milestone in the field of In-situ correlative microscopy and has the potential to revolutionize the way you perform correlative analysis.

Subscribe to our newsletter to make sure you are the first to get all the latest news!

LiteScope 2.5 introduces:

- In-situ multimodal & correlative analysis

- Optimized & time-efficient workflow

- Ultimate performance inside SEM

- Open-hardware design for easy customization

Check our introduction video below by our CEO Jan Neuman. For more details, don't hesitate to contact us!

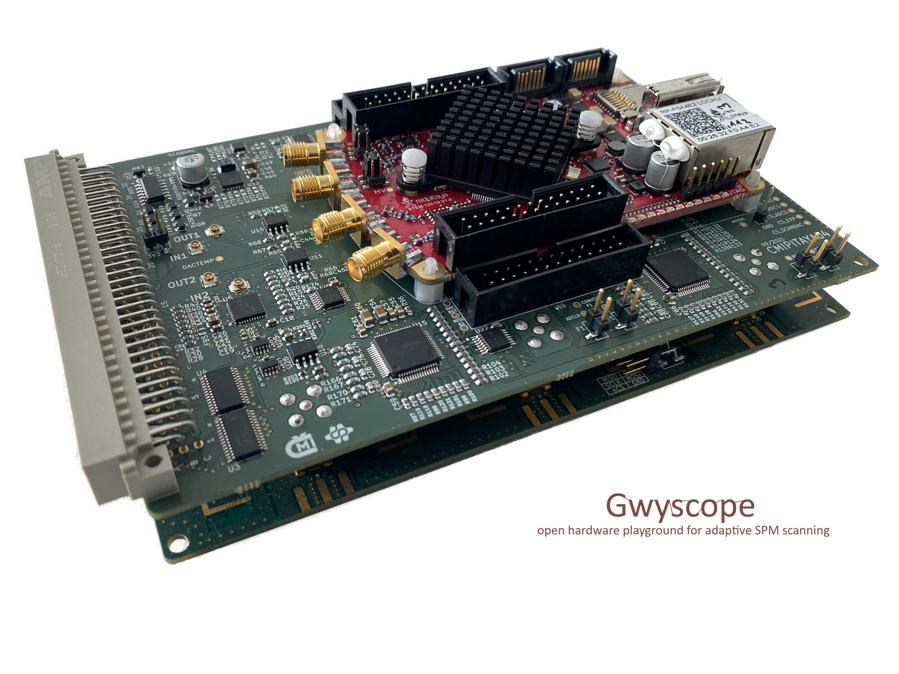

The new generation of LiteScope AFM-in-SEM is built on the completely new state-of-the-art control unit NenoBox leveraging the performance and capabilities of the AFM-in-SEM to a new level. The heart of the new control unit is the Open Hardware concept of the DSP controller GwyScope. We have implemented several key features that will revolutionize the market, using the AFM-in-SEM for various applications.

LiteScope 2.5 presents

Ultimate performance inside your SEM

With the help of LiteScope, you can quickly and accurately analyze complex data sets thanks to its compact design and a state-of-the-art digital signal processing unit. That means faster and more reliable results with ultimate resolution.

- The atomic Z-axis resolution and noise floor up to 35 pm assures higher accuracy and resolution for sample characterization.

- Two integrated fast lock-in amplifiers and numerous high-frequency inputs and outputs are pushing the limits of possible mechanical, electrical and magnetic in-situ analysis.

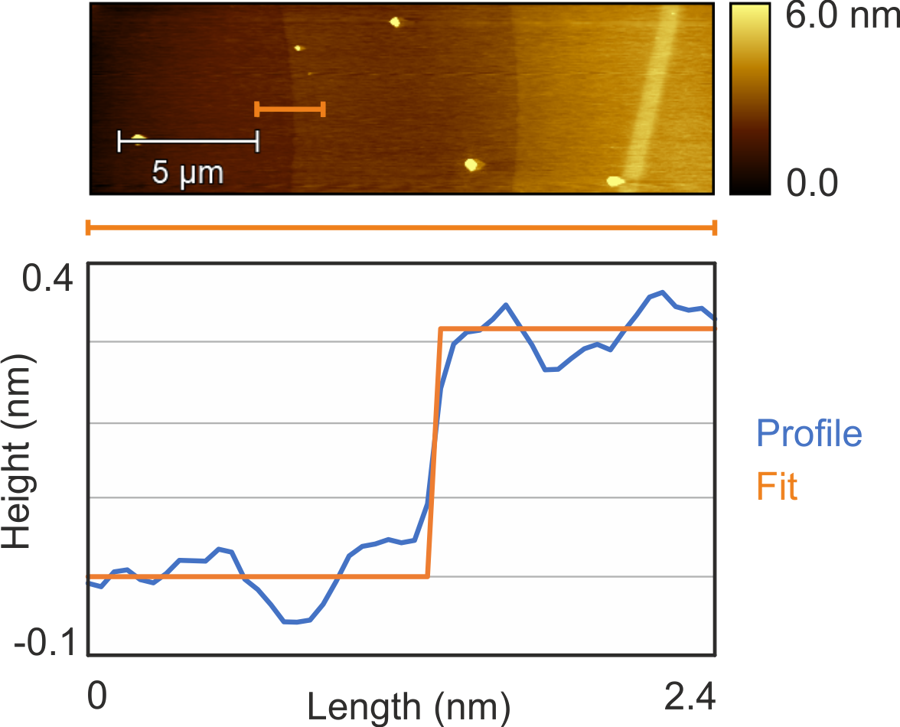

Reference sample:

- Sample: Si atomic terraces

- Analysis: CPEM, simultaneous AFM and SEM

Measurement results:

- Step height: 314 ± 40 pm

- RMS roughness of the terrace: 72 pm

- Noise floor up to 35 pm

We are adding two measurement modes

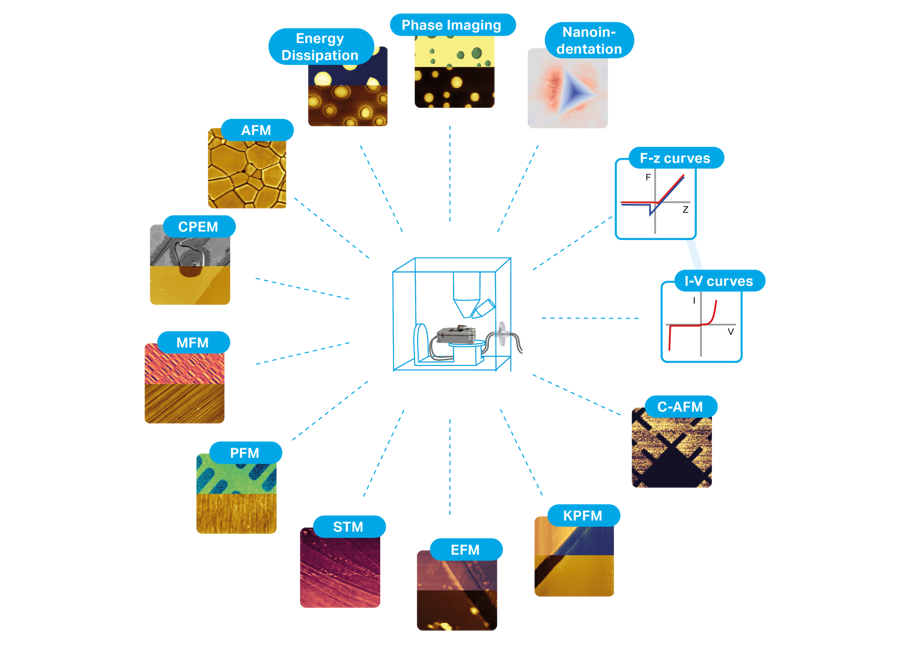

The extended range of analyzed properties allows you to choose from 14 AFM techniques. It enables the analysis and characterization of various properties with high precision and accuracy for comprehensive in-situ analysis of samples. See the newly introduced modes:

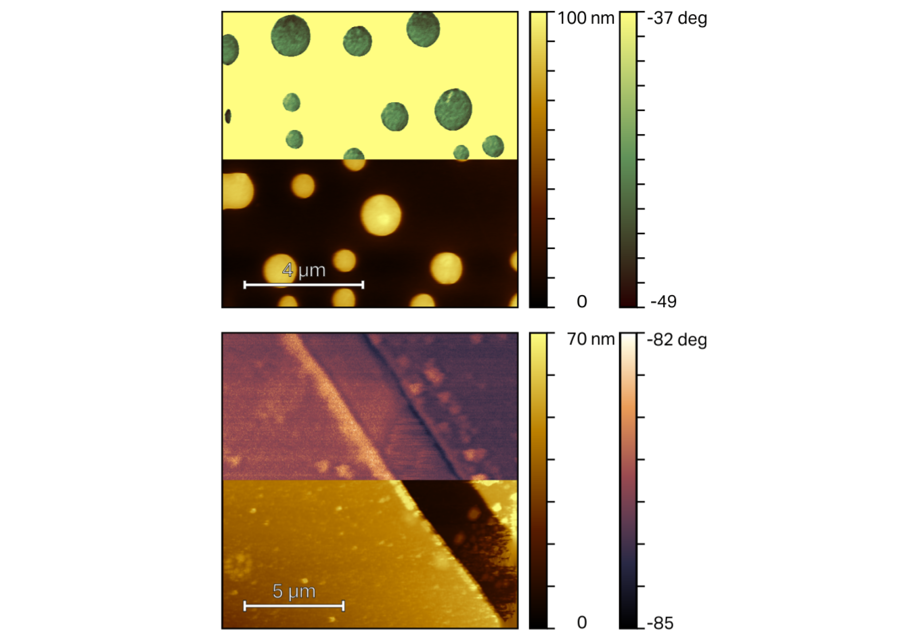

Phase Imaging

Phase imaging is a technique used to map variations in surface properties such as elasticity, adhesion, and friction. It works as a one-pass technique which detects the phase between the probe driving signal and probe oscillation signal while maintaining the constant amplitude of the oscillations.

Electrostatic Force Microscopy (EFM)

EFM maps the electrical properties of a sample surface by detecting the electrostatic force between the surface and a biased AFM tip which provides useful, qualitative information on electric field gradients of a sample surface.

The most comprehensive AFM-in-SEM tool on the market

- Improved performance of all available measurement modes

- All techniques available with no need for additional hardware

- Compatibility with all self-sensing probes on the market

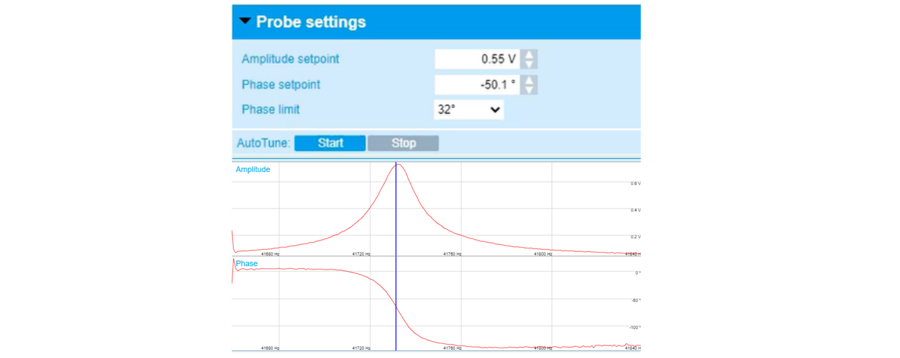

- Method-based automatic probe tuning with presets for efficient workflows

Optimized workflow and easy-to-use operation

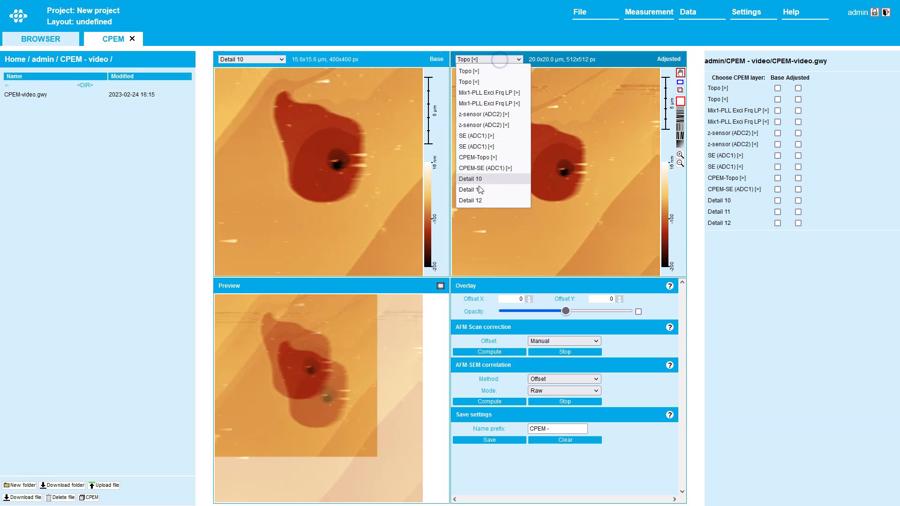

Redesigned UI is tailored to be more user-friendly and efficient, providing users with the most important information at their fingertips:

- Redesigned UI optimized for automated operations and offering many benefits for the user.

- Probe auto-tuning functionality

- Predefined workflows for a variety of measurement modes

- The possibility to fully customize many parameters assures even better fine-tuning of your measurements.

The efficiency of the image correlation:

- Complex tasks are easily performed with just a few clicks, reducing the time and effort needed for sample characterization.

- Stronger AI computing power was introduced.

- Automated (AI-driven) corrections of AFM image artifact

- Automated correlation of AFM and SEM data via CPEM+ functionalities

Based on the open-hardware design

LiteScope 2.5 control unit is based on the state-of-the-art Digital Signal Processor GwyScope, fully integrated into the commercial product. Innovative design with digital diagnostics allows fast and easy device service via an on-site exchange, reducing downtime and improving efficiency.

- Open Hardware concept of the DSP controller geared towards customer modifications for new measurement approaches

- Improved connectivity with a variety of external devices for a possible performance of advanced non-standard experiments

- In-built digital system diagnostics with fast & easy device service via on-site exchange

Interesting improvements? That's not all. Learn more about all advantages of LiteScope!

Interested in more details?