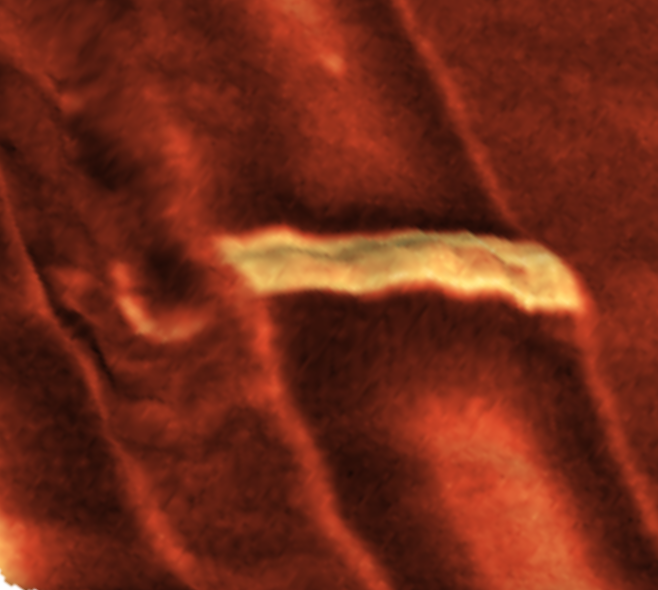

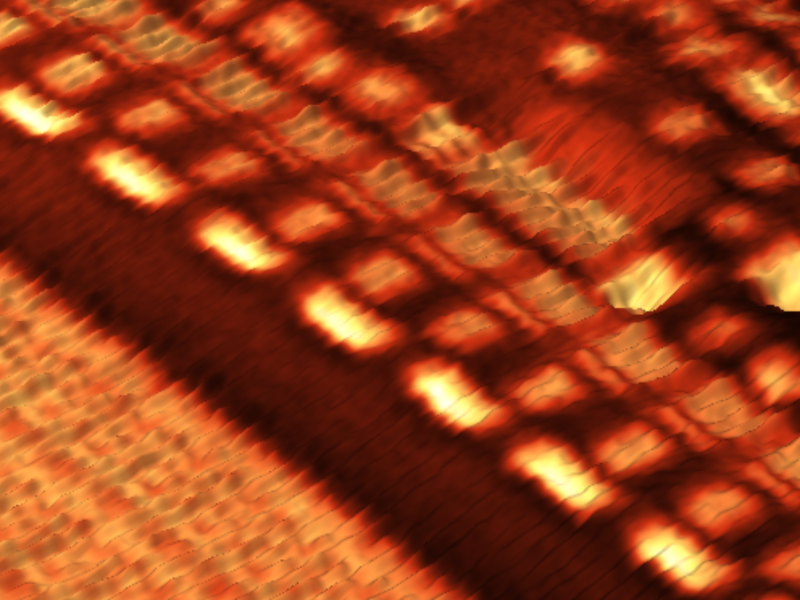

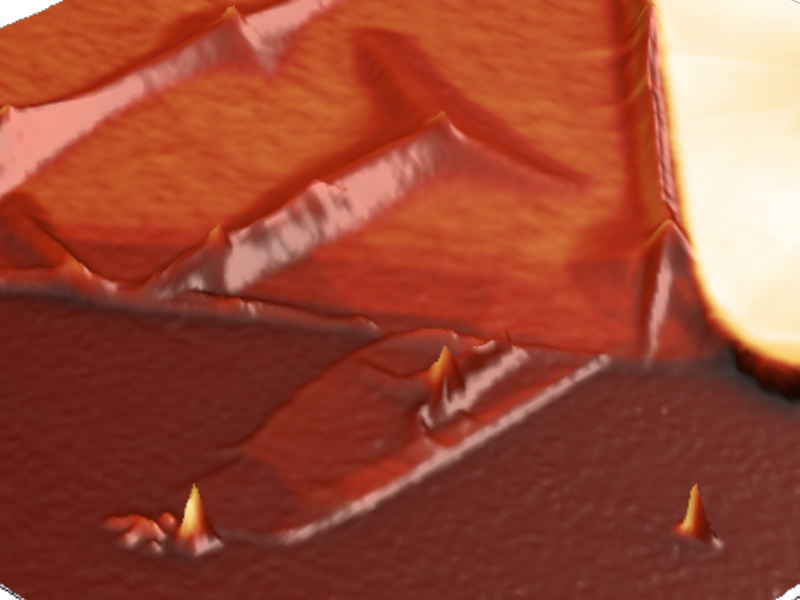

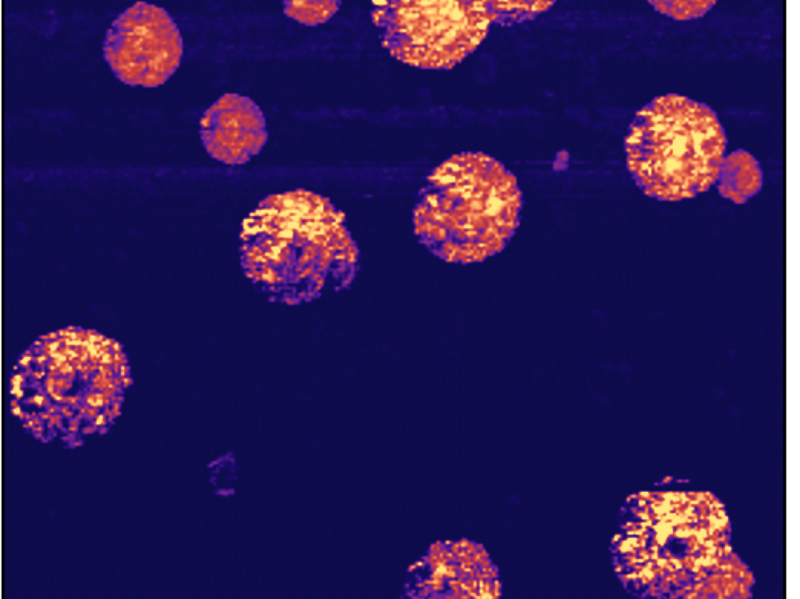

FIB polishing of CdTe

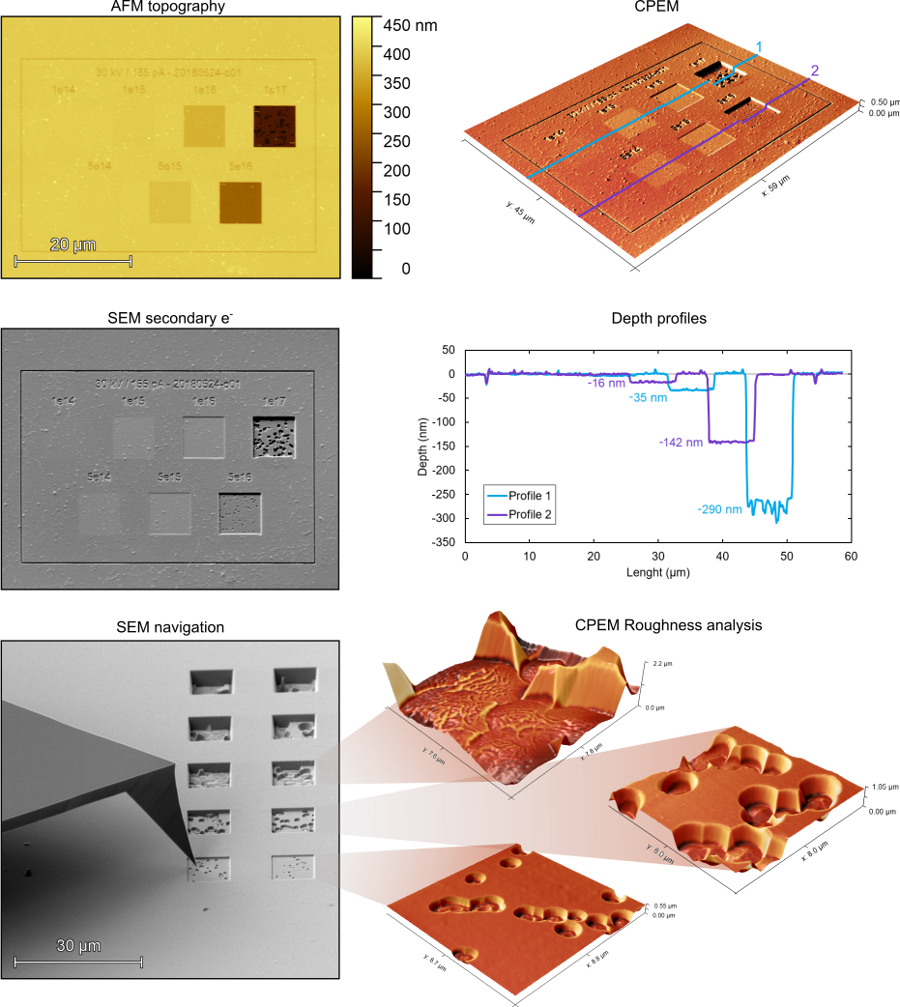

Cadmium Telluride composite material was milled by a focused ion beam (FIB) using different ion doses. Using the LiteScope inside the SEM chamber, we could easily localise to the region of interest and in-situ investigate each area separately, resulting in a roughness-ion dose relation.

This surface analysis was done in-situ right after the FIB milling without chamber evacuation. As a result, it became possible to find the optimal parameters of polishing CdTe material and to do a surface quality control to keep desired surface roughness.

Measurement modes: Topography

LiteScope benefits:

- Fast and easy ROI identification

- In-Situ conditions: combined AFM and SEM analysis of sensitive sample

- Depth and height profiling with sub-nm precision

Sample courtesy of Veronika Hegrová, CEITEC

Want to discuss your own application ?