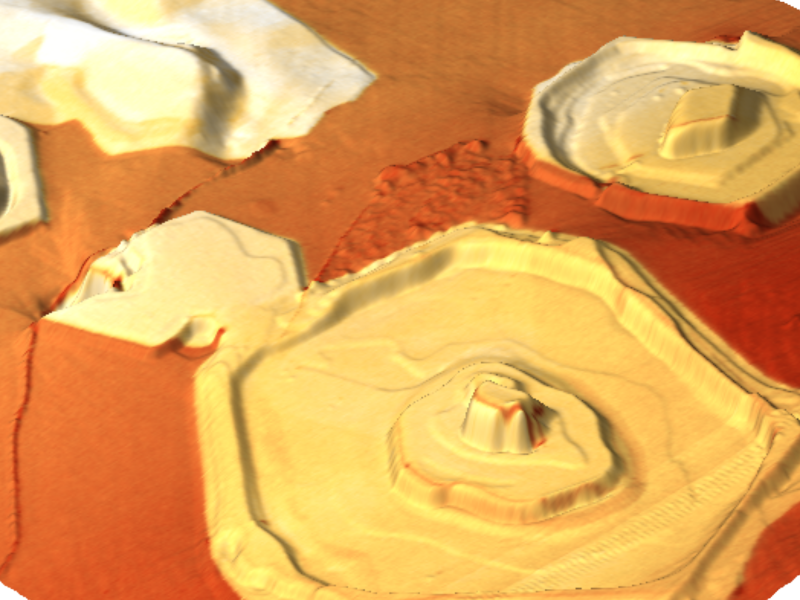

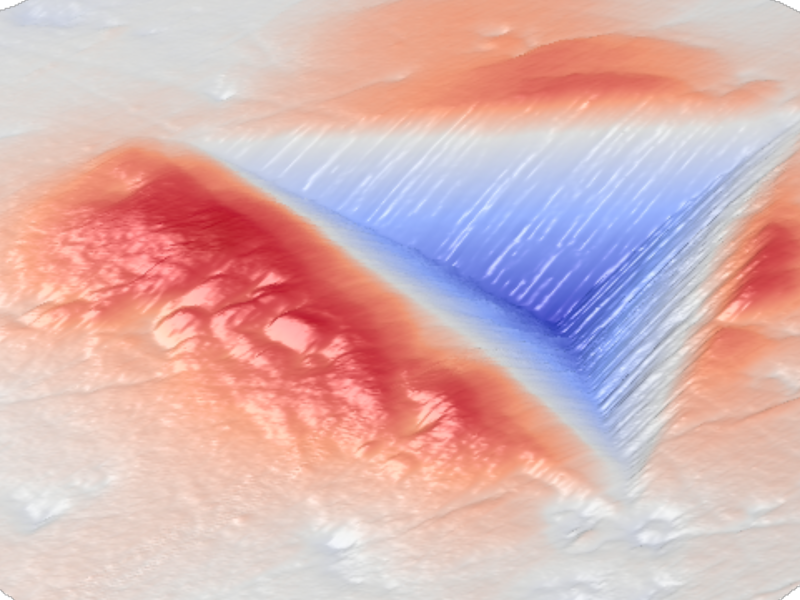

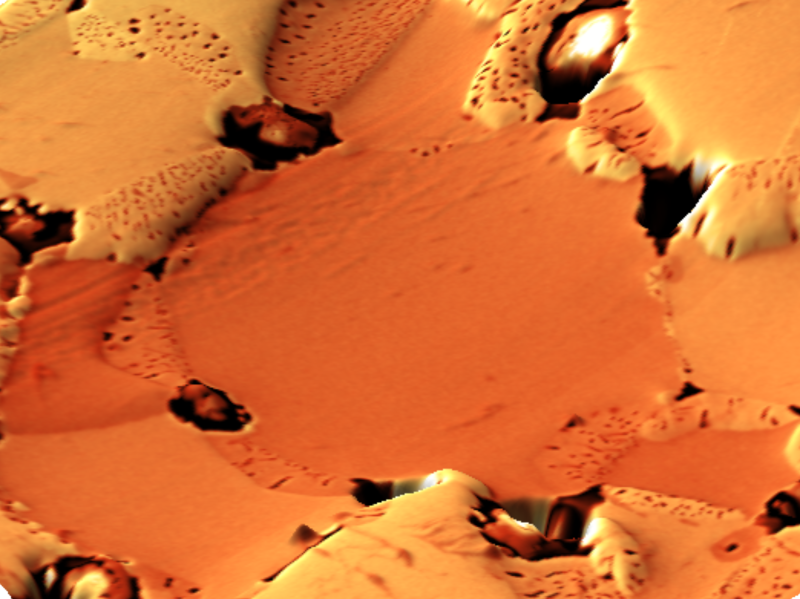

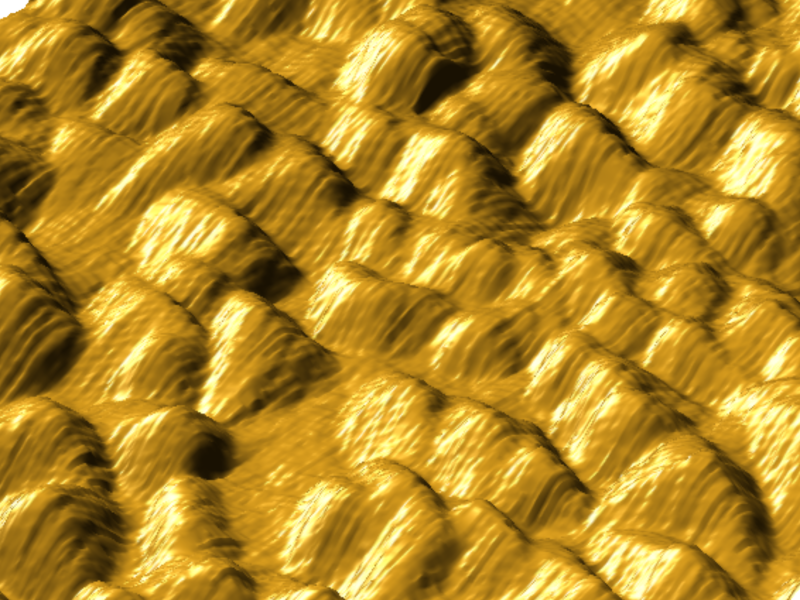

Material science applications

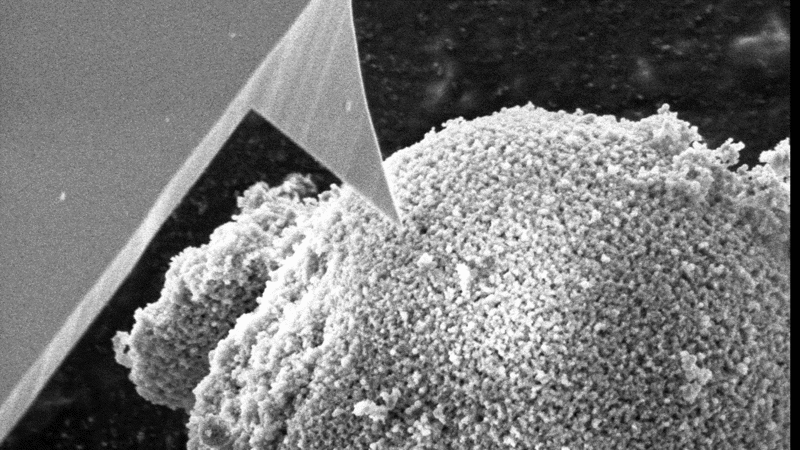

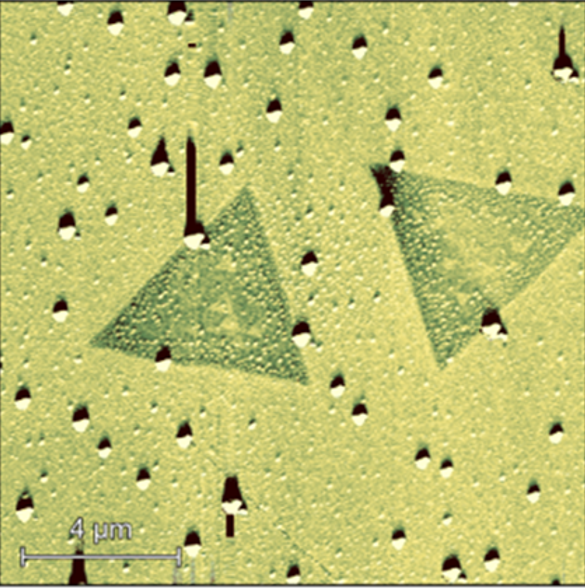

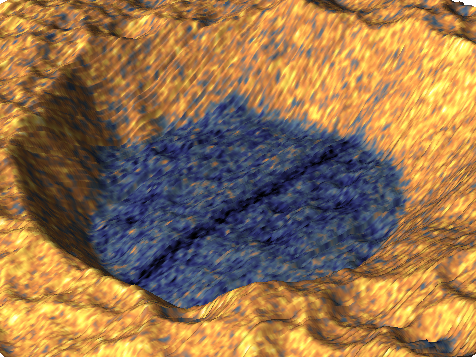

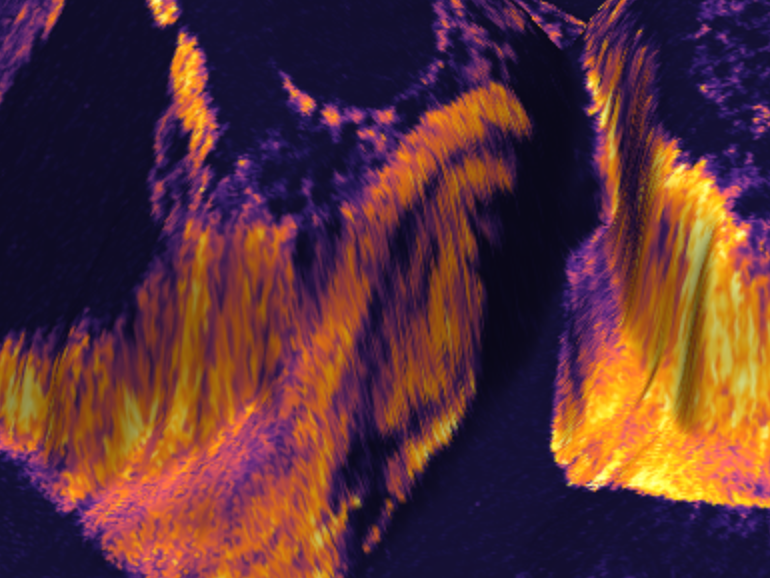

Innovative materials play essential roles in many modern technologies advancements. Researches need to have deeper understanding of structural, mechanical, chemical, electrical, and magnetic properties of materials in nanoscale. Providing better understanding, revealing specific characteristics and assuring quality of materials are indispensable.

LiteScope means the establishment of a new level of material in-situ analysis. Whether you research in field of nanowires and 1D materials, thin films, graphene and other 2D materials, or you dedicate to steels & metal alloys, ceramics, polymers & composites or battery research, LiteScope will help you to uncover all the nanoscale secrets of materials.

Application examples

See application notes

Want to discuss your own application?