Semiconductor Failure Analysis

Semiconductors are the foundation of modern electronics, enabling everything from computing to data storage. As devices shrink and become more complex, precise failure analysis is critical.

Failure Analysis with AFM-in-SEM LiteScope integrated directly into the FIB/SEM environment, enables in-situ, site-specific electrical and topographical characterization of semiconductor components at the nanoscale. It delivers precise dopant profiling and conductivity mapping without compromising sample integrity.

"NenoVision represents the best case of developing an idea into a real business in the attractive field of advanced metrology. We are interested in semiconductor applications of correlative microscopy for R&D and production of semiconductor materials and devices, especially wide bandgap structures. NenoVision’s LiteScope AFM-in-SEM has been successfully demonstrated on our silicon carbide samples, and together with its Scanning Spreading Resistance Microscopy (SSRM) mode, it opens up new opportunities in advanced semiconductor analysis."

Key Benefits & Features

Navigate directly to specific vias, transistors, or doped layers and perform localized electrical AFM analysis with nanoscale precision.

Perform sample preparation and in-situ analysis within the same vacuum cycle, avoiding surface oxidation or contamination.

Eliminate time-consuming sample transfers and redundant tool usage — streamline failure localization into a single workflow.

Application areas

NAND Flash memory

SRAM & Logic circuits

Transistors (FinFET, CMOS, ...)

SOI & Advanced nodes

Thin films

„LiteScope empowers us to conduct comprehensive, correlative studies of devices and materials properties while unlocking versatile in-situ ion beam milling and deposition for sample preparation. We're thrilled to be working with the NenoVision team to push the boundaries of this platform and uncover its full potential in the realm of emerging nanoelectronics.“

Nanoelectronics Metrology & Failure Analysis Lab

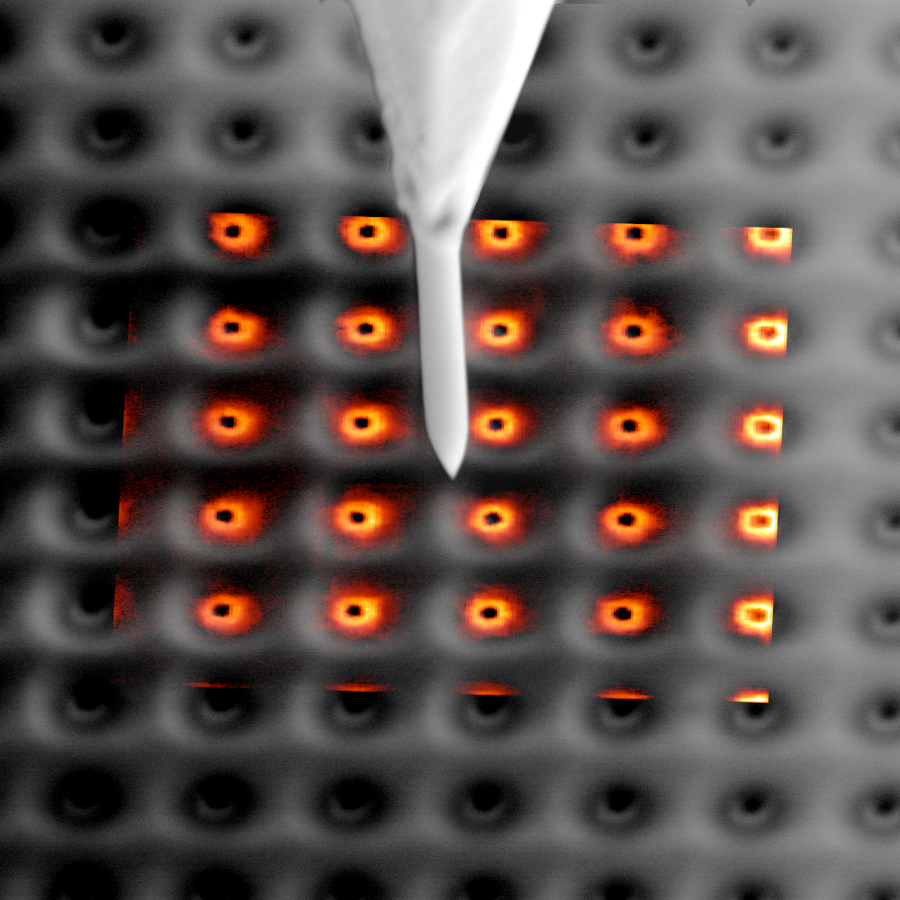

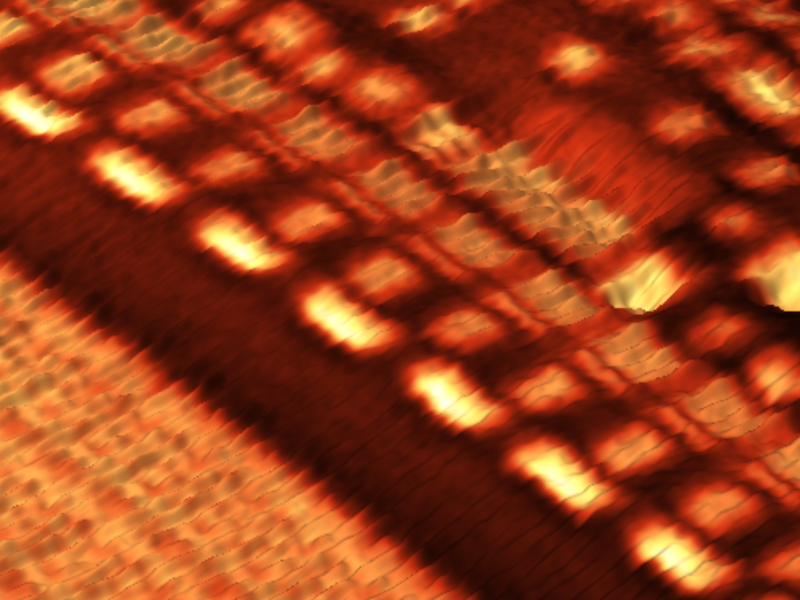

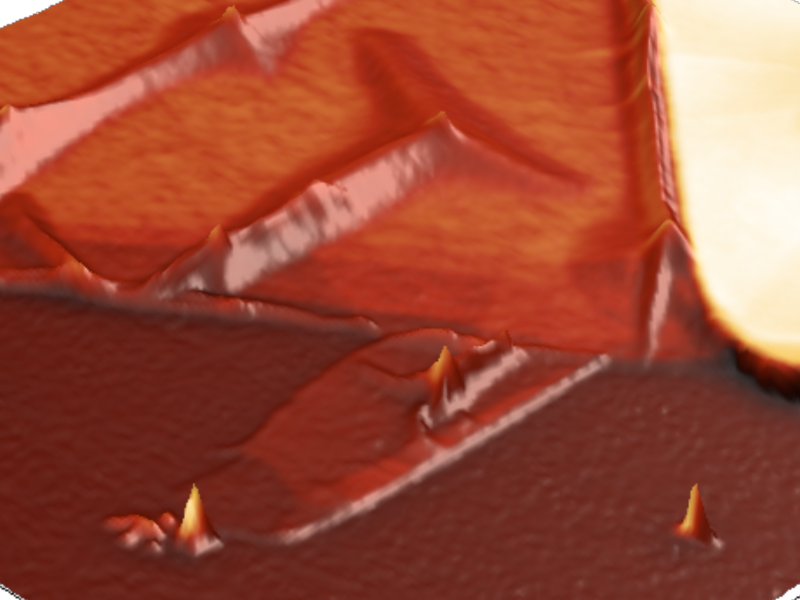

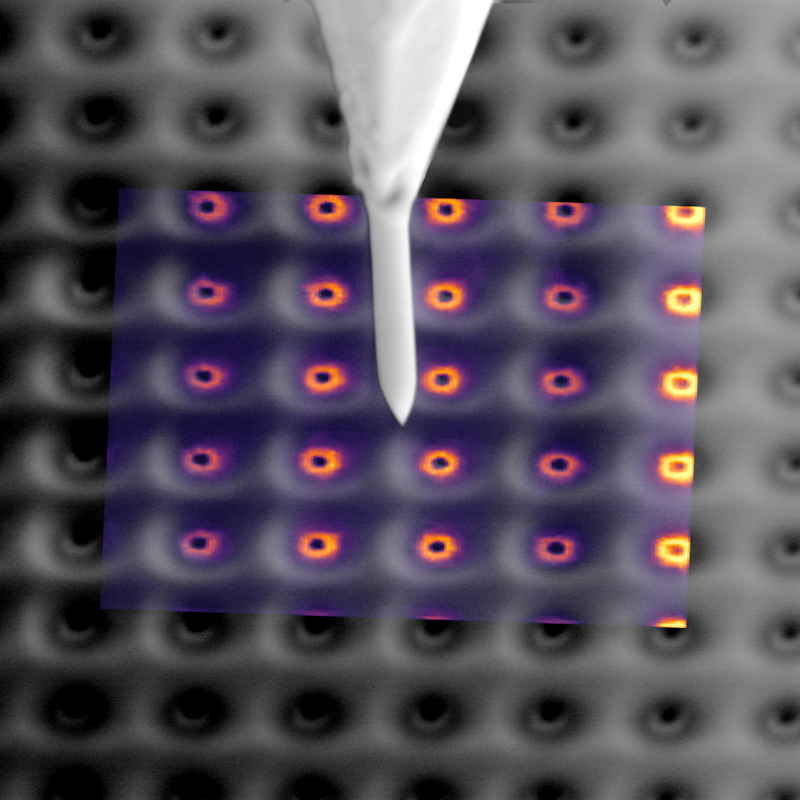

Failure analysis of a NAND structure

We used AFM-in-FIB/SEM to analyze NAND structures, identifying specific vias, sequentially delayering them using PFIB and then characterizing them layer by layer. C-AFM and I/V spectroscopy provide high-resolution electrical characterization, with results correlated to SEM techniques for accurate semiconductor failure analysis. This approach allows for real-time monitoring and reveals electrical failures at various depths of the structure.

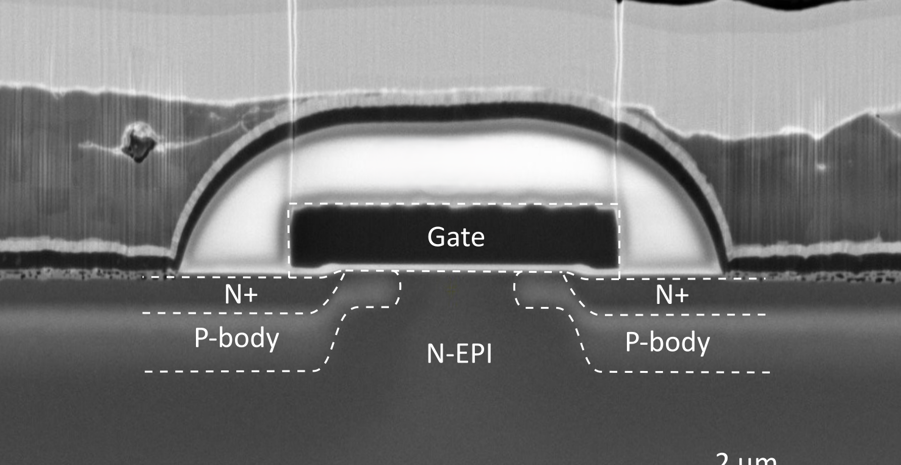

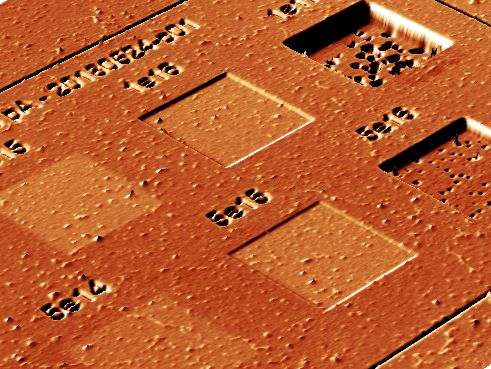

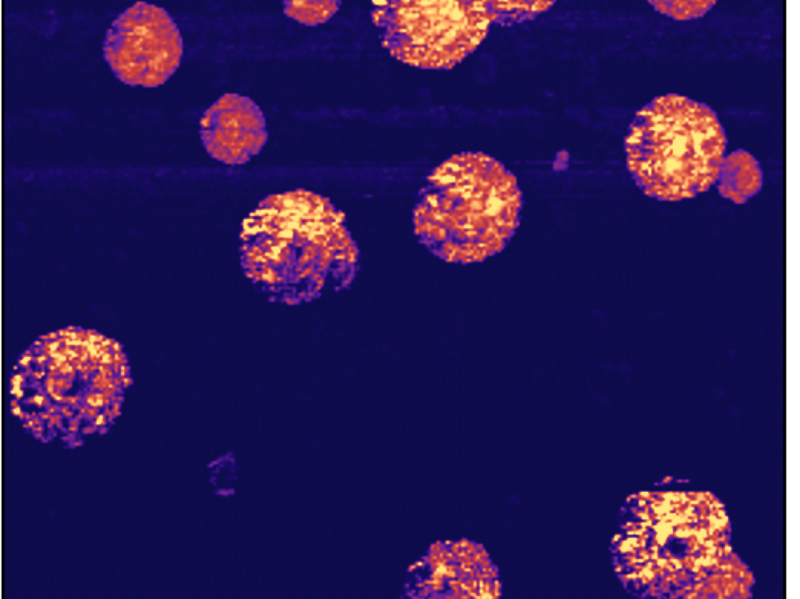

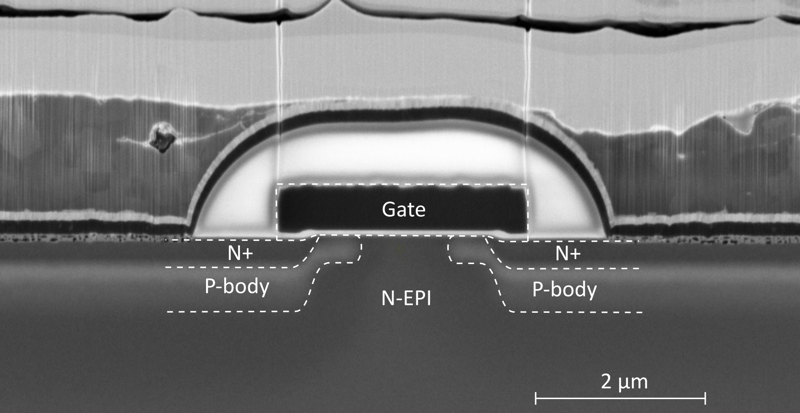

Dopant Concentration Analysis of MOSFET Transistor

SEM-integrated Scanning Spreading Resistance Microscopy (SSRM) was used to map dopant concentration in semiconductor devices (MOSFET Transistor) with nanoscale precision.

In-situ SEM-SSRM approach enables efficient, site-specific electrical characterization of devices by correlating structural imaging with local doping profile, essential for assessing device performance and reliability, enhancing advanced failure analysis.

In SiC MOSFETs, it allows direct analysis of doped layers and junctions, capturing their geometry and uniformity, which is critical for optimizing conductivity and minimizing losses.

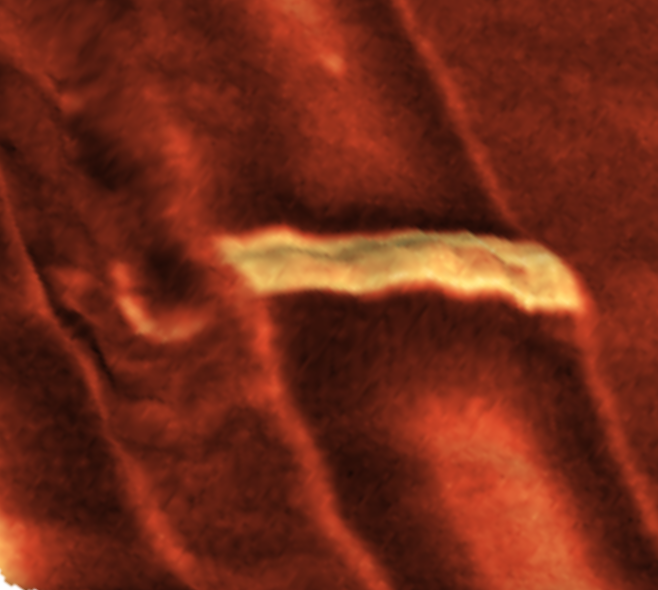

Other application examples

Ready to discuss your own application?

Webinar

Are you interested in learning more about Semiconductor failure analysis with AFM-in-SEM? Join our webinar in May and find out how LiteScope can enhance your R&D process!

Application Note

Product news

Inside the Chip: Semiconductor Failure Analysis with AFM-in-SEM

In-Situ SEM Masterclass at QUT University!

Upcoming Battery Webinar | Unveiling Battery Electrode Secrets with AFM-in-SEM